Inspection Guidelines

Alligator or Fatigue CrackingBleedingBlock CrackingCorrugationDepressionJet Blast ErosionJoint Reflection Cracking From PCCLongitudinal and Transverse CrackingOil SpillagePatching and Utility Cut PatchPolished AggregateRaveling - Dense MixRaveling - Slurry Seal or Coal Tar Over Dense MixRaveling - Porous Friction CourseRuttingShoving of Asphalt Pavement by PCC SlabsSlippage CrackingSwellWeathering - Surface Wear - Dense Mix Asphalt

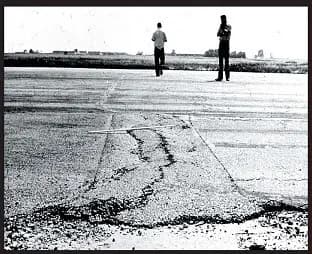

Patching and Utility Cut Patch

A patch is considered a defect, regardless of how well it is performing.

How to Measure

Patching is measured in square feet (square meters) of surface area. However, if a single patch has areas of differing severity levels, these areas should be measured and recorded separately. For example, a 25 square feet (2.5 square meters) patch may have 10 square feet (1 square meter) of medium severity and 15 square feet (1.5 square meters) of light severity. These areas would be recorded separately. Any distress found in a patched area will not be recorded; however, its effects on the patch will be considered when determining the patch's severity level.

| Severity | Distress Example | Description |

|---|---|---|

| Low |  | Patch is in good condition and is performing satisfactorily. Little or no FOD potential. |

| Medium |  | Patch is somewhat deteriorated and affects riding quality to some extent. Some FOD potential. |

| High |  | Patch is badly deteriorated and affects riding quality significantly or has high FOD potential. Patch needs replacement. |