Inspection Guidelines

Cracks - Longitudinal, Transverse, and Diagonal

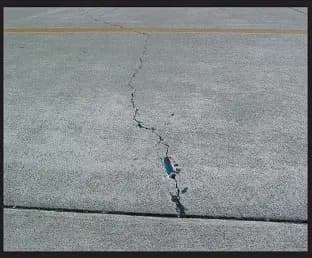

These cracks, which divide the slab into two or three pieces, are usually caused by a combination of load repetition, curling stresses, and shrinkage stresses. (For slabs divided into four or more pieces, see Shattered Slab/Intersecting Cracks.) Low-severity cracks are usually warping- or friction-related and are not considered major structural distresses. Medium- or high-severity cracks are usually working cracks and are considered major structural distresses.

How to Count

Once the severity has been identified, the distress is recorded as one slab. If a crack is repaired by a narrow patch (e.g., 4 to 10 inches wide (100 to 250 millimeters)), only the crack and not the patch should be recorded at the appropriate severity level.

| Severity | Distress Example | Description |

|---|---|---|

| Low |  | Crack has no spalling or minor spalling (no FOD potential). If non-filled, it is less than 3 millimeters (1/8 inch) wide; a filled crack can be of any width, but its filler material must be in satisfactory condition. |

| Medium |  | One of the following conditions exists: (1) a filled or non-filled crack is moderately spalled (some FOD potential); (2) a non-filled crack has a mean width between 1/8 inch (3 millimeters) and 1 inch (25 millimeters); (3) a filled crack has no spalling or minor spalling, but the filler is in unsatisfactory condition; or (4) the slab is divided into three pieces by two or more cracks. |

| High |  | One of the following conditions exists: (1) a filled or non-filled crack is severely spalled (definite FOD potential); (2) a non-filled crack has a mean width approximately greater than 1 inch (25 millimeters), creating tire damage potential, or (3) the slab is divided into three pieces by two or more cracks, one of which is at least medium severity. |